Unlocking Excellence in Metal Fabrication with Precision Mold Parts

In the highly competitive and technologically driven world of metal fabrication, the quality and precision of components are paramount. Among these, precision mold parts stand out as the backbone of manufacturing excellence, enabling companies to achieve tight tolerances, repeatable processes, and superior product quality. At DeepMould.net, we are committed to providing industry-leading precision mold parts that empower metal fabricators across the globe to push boundaries, optimize performance, and realize their production goals efficiently.

Why Are Precision Mold Parts Essential in Metal Fabrication?

Precision mold parts are the fundamental elements that define the accuracy, durability, and efficiency of the molding process. These highly engineered components are designed to withstand extreme conditions, resist wear, and deliver precise dimensional tolerances. Their significance in metal fabrication includes:

- Enhanced Product Quality: Ensuring consistent and high-quality outputs by maintaining tight dimensional tolerances.

- Increased Efficiency: Reducing cycle times and minimizing waste through precise mold function.

- Cost Reduction: Lowering maintenance and rework costs due to superior material and craftsmanship.

- Greater Product Complexity: Allowing for intricate designs and detailed features in metal parts.

- Longer Tool Life: Withstanding repetitive use and reducing downtime for maintenance or replacements.

Key Features of Superior Precision Mold Parts

At DeepMould.net, we understand that the success of any metal fabrication project hinges on the quality of its components. Therefore, our precision mold parts are crafted with meticulous attention to detail, incorporating several critical features:

- Material Excellence: We select high-grade steels, alloys, and composites known for their toughness, thermal stability, and corrosion resistance, such as H13, P20, and S136.

- Advanced Manufacturing Processes: Employing CNC machining, EDM (Electrical Discharge Machining), and laser machining ensures unprecedented accuracy and smooth surface finishes.

- Precise Tolerance Control: Our manufacturing process guarantees tolerances within ±0.02 mm or better, vital for complex and high-precision molds.

- Surface Treatment and Coatings: Applying coatings such as nitriding, PVD, or nickel plating enhances surface hardness, reduces friction, and extends mold lifespan.

- Customizability: Tailoring each precision mold part to meet specific client requirements, including size, shape, and functional features.

The Manufacturing Process of Precision Mold Parts

The journey from raw materials to finished precision mold parts is a complex and highly technical process. Well-executed manufacturing ensures each component meets the highest standards of accuracy and durability. Key steps include:

1. Material Selection and Preparation

Choosing the right material based on the intended application, load requirements, and thermal properties. The material is then cut and prepared for machining.

2. CNC Machining and Milling

Utilizing computer-controlled machines, we remove excess material to form the basic shape of the mold parts with high precision. This stage emphasizes tight tolerances and surface smoothness.

3. Electrical Discharge Machining (EDM)

EDM allows for the creation of intricate features and tiny details required in complex mold designs. It ensures minimally invasive shaping with high accuracy.

4. Heat Treatment and Surface Finishing

Applying heat treatment processes like quenching or tempering improves hardness and strength. Surface finishing techniques such as polishing, grinding, or coating enhance the mold’s surface characteristics.

5. Quality Assurance and Testing

Rigorous inspections, including coordinate measuring machine (CMM) analysis and visual checks, verify dimensional accuracy, surface quality, and functional integrity.

Advantages of Partnering with DeepMould.net for Precision Mold Parts

DeepMould.net has established itself as a leader in the manufacturing of precision mold parts by consistently delivering products that surpass client expectations. Here are some benefits of choosing us as your trusted partner:

- Unmatched Quality Assurance: Our quality control protocols follow international standards, ensuring every part meets or exceeds industry benchmarks.

- Advanced Technology: We invest continuously in cutting-edge machinery and process automation to produce highly precise components.

- Custom Design Expertise: Our engineering team collaborates with clients to develop customized solutions tailored to unique project needs.

- Rapid Turnaround Times: Efficiency in production and logistics guarantees timely delivery without compromising quality.

- Competitive Pricing: Our optimized manufacturing processes allow us to offer premium precision mold parts at cost-effective rates.

Industries Benefiting from Precision Mold Parts

The application of precision mold parts spans numerous high-demand industries, including:

- Automotive: For producing complex engine components, body parts, and interior fixtures.

- Electronics: Creating high-precision molds for connectors, housings, and micro-components.

- Medical Devices: Manufacturing intricate molds for surgical instruments and implants.

- Aerospace: Crafting reliable, high-performance components resistant to extreme conditions.

- Consumer Goods: Enabling high-quality molds for durable and aesthetically detailed products.

Innovative Trends in Precision Mold Parts Manufacturing

As technology continues to evolve, so does the landscape of precision mold parts. Leading manufacturers like DeepMould.net are integrating innovative techniques such as:

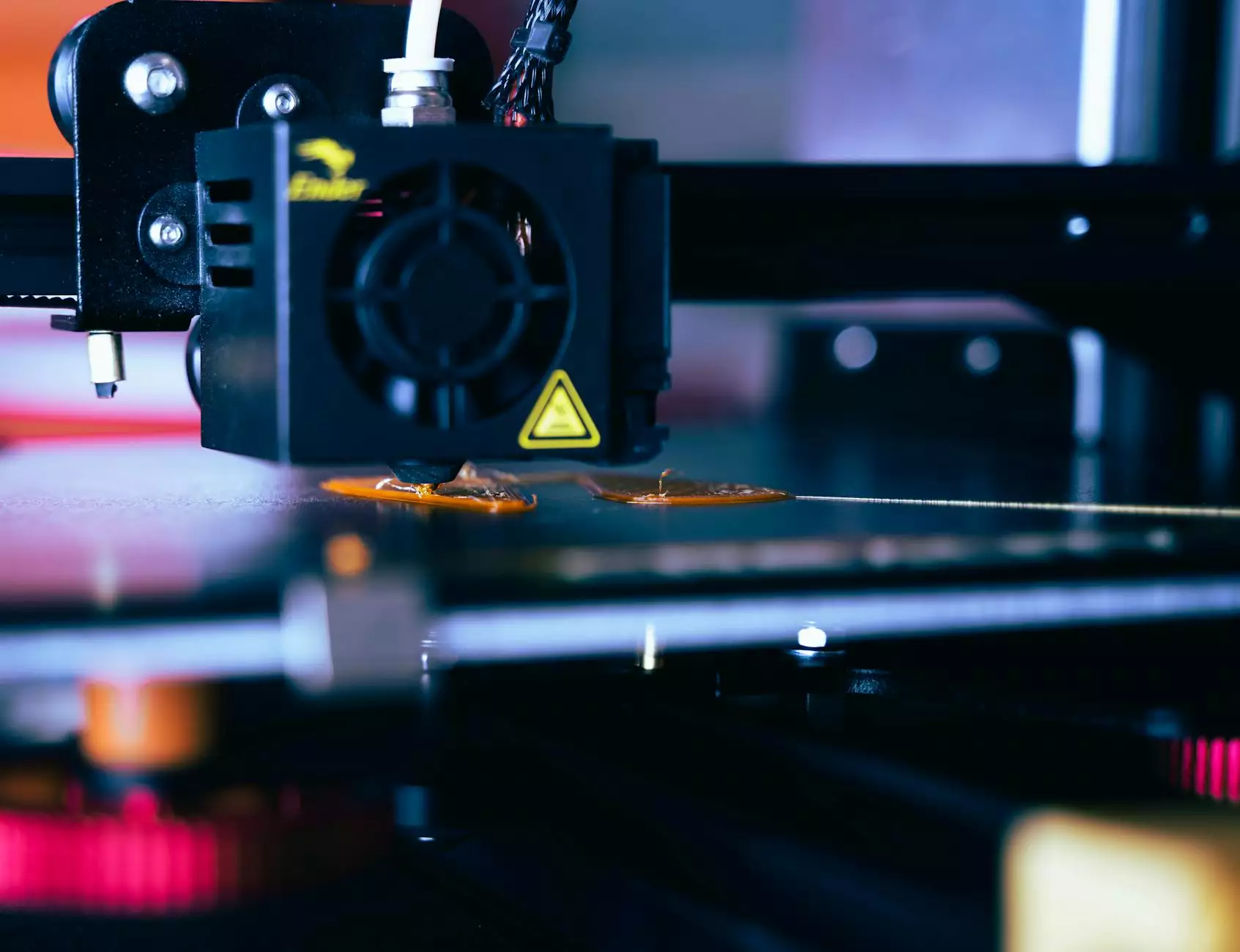

- Additive Manufacturing (3D Printing): For rapid prototyping and producing complex internal features.

- Simulative Design Software: To optimize mold parameters and predict performance before manufacturing.

- Smart Manufacturing: Implementing Industry 4.0 principles for real-time monitoring and quality control.

- Eco-Friendly Processes: Reducing environmental impact through sustainable materials and energy-efficient machinery.

Conclusion: Elevate Your Metal Fabrication with Precision Mold Parts

In conclusion, the role of precision mold parts in metal fabrication cannot be overstated. Their contribution to product accuracy, process efficiency, and cost-effectiveness makes them indispensable for modern manufacturing enterprises aiming for excellence. DeepMould.net, with its commitment to quality, innovation, and customer satisfaction, stands as your ideal partner for sourcing top-tier precision mold parts.

By choosing us, you harness the power of industry-leading technology, expert craftsmanship, and tailored solutions designed to meet the most demanding specifications. Experience the difference that high-quality precision mold parts can make in elevating your manufacturing processes to new heights. Contact DeepMould.net today and take the first step toward manufacturing mastery.